Caterpillar 349E Excavator Repair – C13 Engine Injector and Wiring Harness Replacement

Introduction

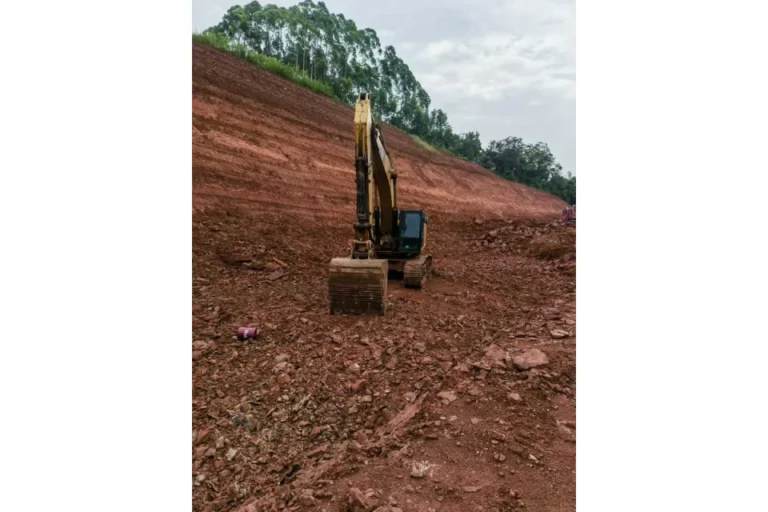

The Cat 349E is a big machine built for hard digging. Ours came in from a jobsite where it had been moving red clay day after day. It runs a C13 engine, which is usually tough, but this one had started to act up—low power, drinking more fuel than normal, and puffing out black smoke whenever the operator pushed it hard.

When we opened the side covers, we could already smell raw diesel mixed with hot oil. That was our first clue the injectors and wiring weren’t doing their job anymore. This repair was about getting the engine back to reliable working order without pulling the whole machine out of service for too long.

The operator told us the machine had been harder to start in the mornings, and once it warmed up it just didn’t pull like before. On heavy loads, the bucket stalled quicker than usual. We also noticed the exhaust was darker than it should be.

A quick look at the filters showed dirtier fuel than expected. That, along with the smoke and sluggish power, pointed straight at the injection system. The wiring harness looked brittle too—heat and vibration take their toll over the years.

Step-by-Step Repair

1. Field Inspection

We parked the 349E on level ground, pulled the side doors open, and got a good look at the C13. Dust from the site covered everything. Before touching anything, we checked pressures and temperatures. Nothing was out of safety limits, but the idle was unstable. That confirmed it was time to dig deeper.

2. Fuel and Hydraulic Filters

The fuel filters came off first. Cutting one open showed a lot of fine debris. No surprise the injectors were struggling. We replaced those filters straight away, but we knew that alone wouldn’t solve the main issue.

3. Valve Cover and Engine Top End

We removed the valve cover. As soon as the bolts came loose, oil that had been trapped around the gasket dripped down. Underneath, the rocker arms and injectors were coated in dark, sticky oil. It’s a sight every mechanic knows: injectors that have worked way past their best.

4. Injector Replacement

New Cat injectors had been ordered ahead of time. We pulled the old ones—each showed signs of wear and carbon buildup. The new injectors slid in cleanly. Every bolt was torqued by hand with the right spec, no shortcuts. Once in, the difference was clear: tight fit, fresh seals, no leaks.

5. Wiring Harness

Next came the harness. The old one had brittle plastic and a couple of connectors that didn’t lock right anymore. That’s enough to cause misfires. We routed the new harness carefully, clipped it into place, and checked each connector twice. Nothing is worse than a loose connection after reassembly.

Reassembly and Testing

With injectors and harness installed, we buttoned up the valve cover, checked fluids, and bled the fuel lines. Then came the moment of truth—key on, start.

The C13 fired after a couple of turns, then settled into a steady idle. No shaking, no extra smoke. We let it warm up while watching oil pressure and coolant temp. Everything held steady. A quick throttle test showed clean acceleration without the lag it had before.

Results After Repair

Working on heavy equipment like the Cat 349E reminds us how much depends on timely maintenance. Injectors and wiring harnesses may look small compared to the rest of the machine, but when they fail, the whole job slows down.

In this case, swapping them out brought the engine back to life. The customer saved money, the machine saved fuel, and the crew could keep moving earth without worrying about downtime.

Conclusion

Once the engine went back into the machine, the difference was clear. Power returned, smoke was gone, fuel use dropped. The owner was smiling—he got his C15 back without spending for a replacement.

Takeaway

f the Caterpillar C15 engine starts showing the classic signs: loss of power, high oil use, dark exhaust—it’s smarter to rebuild than to keep patching. This job reminded us that with patience, the right tools, and genuine parts, you can bring a worn-out C15 back to full health and save a fortune in the process