Final Drive Oil Leaks: Causes, Diagnosis and FixesIntroduction

Introduction

The main problem of final drive is oil leaking. if you ignore oil leaking at the beginning, you will get the gears, bearings are damaged and the track is not moving.

Let’s talk about why it happens, how you can spot it early, and the smartest ways to deal with it.

Why Do Final Drives always Leak Oil?

From my experience, leaks usually trace back to a handful of reasons:

Seals give up – They do the heavy lifting. Once they harden or crack, oil slips past.

Bad fit or wear – If parts inside are worn or not aligned, the seal won’t sit tight.

Too much pressure – When the hydraulic system runs hot or overloaded, seals simply can’t hold it in.

Wrong or dirty oil – I’ve seen machines running the wrong grade of oil, and the result is always the same: faster wear.

Worksite knocks – Rocks and debris can nick the casing. Once the housing cracks, leaks follow.

What Oil Leaks Look Like (Real Cases)

Instead of a boring list, let me share a few scenes you might recognize:

Case 1: A Cat 320D leaving a little puddle under the right track every night. Not a hose leak like the operator thought—just a tired seal.

Case 2: A Komatsu PC200 belching a puff of white smoke on a turn. The oil was spraying onto hot steel and burning off instantly.

Case 3: A XCMG excavator unit that suddenly felt sluggish. The track made a clicking noise too. Opened it up—hardly any oil left inside and the gears were chewed.

Case 4: A machine that suddenly “drank” oil. Topping up twice as often? That’s almost always a hidden leak.

👉 If you’ve seen any of these, don’t brush them off. They’re the warning lights of your final drive.

How to Check for a Leak

I usually follow a simple routine:

Look around – Check the hub and bolts for wet spots.

Run a finger test – If your hand comes back oily, you know the answer.

Watch the oil level – Dropping faster than normal? You’ve got a leak.

Open it up – Sometimes you just have to pull it apart to be sure.

It’s not rocket science, but catching it early makes all the difference.

Fixing the Problem

Not every leak means a new final drive. The fix depends on what you find:

Swap the seals and O-rings – 7 out of 10 leaks come from here.

Patch or replace the housing if it’s cracked.

Drain the wrong oil and refill with the right grade.

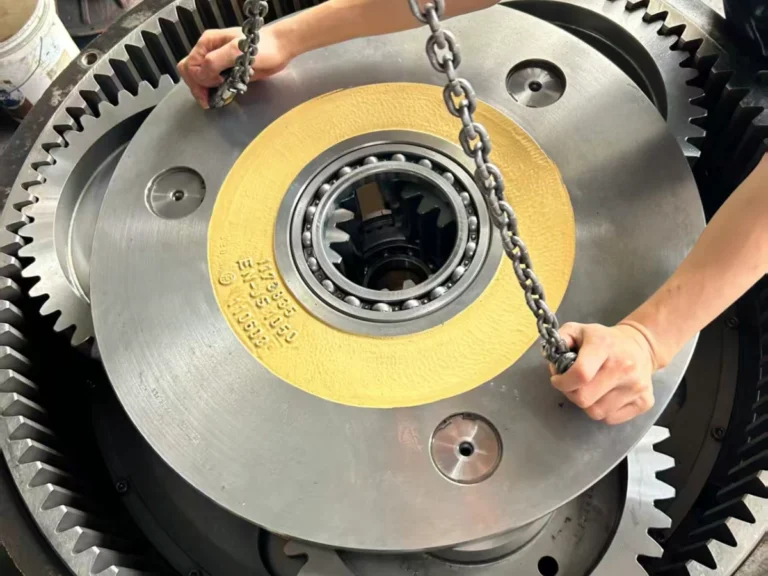

Replace badly worn bearings or gears.

And when it’s all too far gone—just fit a new drive. It costs less than fixing the same problem three times.

How to Stop It from Happening Again

Q: How long should I check oil?

A: Once a week works for most. If your machine works 12-hour shifts in mud, check mid-week too.

Q: Can I get away with cheaper seals?

A: You can, but don’t expect them to last. I’ve seen non-OEM seals fail in a month. OEM parts save headaches.

Q: What about mud and sand?

A: Clean it off every day. Dirt eats seals faster than anything.

Q: Only old machines leak, right?

A: Nope. I’ve seen brand-new drives leak because they were installed wrong or pushed too hard.

Conclusion

Oil leak is one of the most headache problems with final drives, but they’re also one of the easiest to solve. Attention for stains, listen for changes, check the oil, and fix small issues before they become big ones.

👉 Need parts? We stock genuine Komatsu, Caterpillar, and Perkins final drive components. Contact us

today for quick support.